ABOUT US

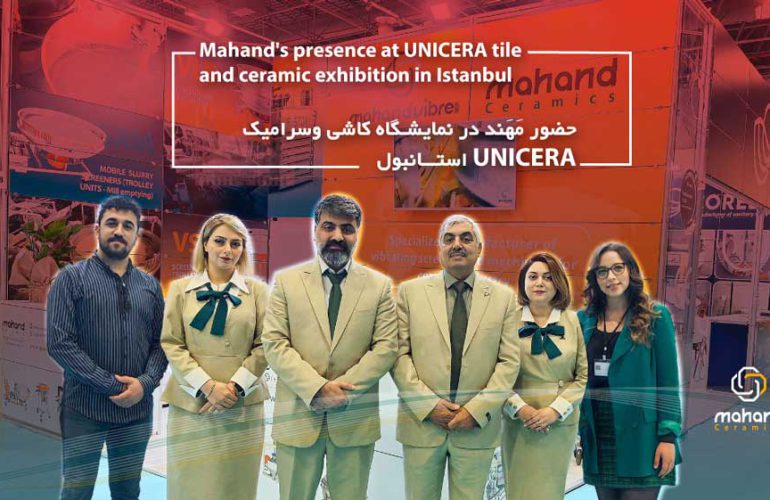

Mahand Ceramic Company has been designing and manufacturing machines for the tile and ceramic industry since 1362. With over 40 years of experience, we proudly stand as the premier and sole specialized manufacturer of vibrating screens (vibrating sieves) in the Middle East, catering specifically to material separation operations within the tile and ceramic sector.Backed by a team of seasoned engineers, we offer a diverse range of machinery tailored to the needs of the tile and ceramic industry.

Our group has established offices in Mashhad, Yazd, Tehran, and Turkey, strategically positioning ourselves to better serve our clientele.

As pioneers in the ceramic tile industry, we are committed to delivering reliable, high-quality products coupled with exceptional service through our professional team across various sectors. Our company offers a comprehensive range of vibrating sieves, including glaze, slurry, and powder screening equipment, designed to effectively separate all types of particles across wet, dry, and liquid materials.

Our round vibrating sieves represent the next generation of this technology, offering enhanced efficiency and versatility. Available in single or multiple floors with varying sizes and diameters to accommodate different needs and capacities. Currently, a significant portion of the country’s tile and ceramic, sanitary porcelain, and container factories entrust us with their screening needs.”

statistics

5000

Customer

40

Device diversity

40

Years of experience

BLOG

Specialized manufacturer of machinery for the tile and ceramic industry

MAHAND

In compliance with quality and European standards

Joint product of Iran and Italy

Customer orientation

has always helped to increase the quality of our products.

Experience and Knowledge

has turned Vibrating into an unrivaled hub in the Middle East.

Up To Date

Consult with us

TO CONTACT SALES EXPERTS, FILL OUT THE FORM BELOW.

Comments from some customers

Takceram Company has purchased two vibrating slurry sieves from Mahand Engineering Company and thank God, we have not had any problems so far. Thank you for Mahand’s good after-sales service.

We would like to express our sincere gratitude for the excellent after-sales service and periodic visits that you have provided for the equipment that we have purchased from your company. We are very pleased with the level of service that we have received, and we are grateful for your prompt and professional attention to any issues that we have had

About a year ago, we needed vibrating screen machines on the press for the production line of Niloufar Tile Factory, which produces 7 to 8 thousand meters of wall tile per day. In the end, we decided to buy a hopper press sieve from Mahand Vibrator Company. Mahand sieves are much more affordable and of better quality than Italian sieves, and they perform better. I would like to thank Mahand Company for all their services

We needed a vibrating screen for the top of the press and the glazing lines. After much searching, we found Mahand and ordered the right screen. We are very satisfied. The sieving and separation of powder and liquids is working well. Thank God, our machines have not had any technical problems and we would like to thank the Mahand team for their after-sales service.

کارخانه کاشی کسری به دلیل تولیدات با کیفیت کاشی و سرامیک، تقریبا 2 الی 3 سال به دنبال یک سرند ویبره با کارایی بالا، مطابق با نمونه های ایتالیایی بود.

در نمونه های داخلی و خارجی تحقیق کردیم، تا با شرکت مهند آشنا شدیم. سفارش ساخت سرند ویبره با کیفیت را دادیم و خداروشکر خیلی راضی هستیم. کاملا با نمونه های خارجی دستگاه رقابت میکنه. ممنون از تیم خوب و پرقدرت مهند

در شرکت لعابیران برای بحث تکنولوژی تولید مواد اولیه خاص به سرند ویبره تخصصی نیاز داشتیم و گروه صنعتی مهند را پیدا کردیم. با خرید غربال ارتعاشی از شرکت مهند ویبره، برای اولین بار در ایران شاهد بازدیدهای دوره ای و خدمات پس از فروش واقعی بودیم. من بابت همه ی خدمات تیم خوب مهند نهایت تشکر را دارم.

سرندویبره ای که از شرکت مهند خریداری کردیم، از نظر قدرت موتور عالی است. با حداکثر ظرفیت و کارایی بالا کار می کند.

خروجی مواد خیلی خوب است و هیچ مشکلی در بخش الک کردن لعاب و دوغاب، جداسازی محصولات، پمپ و همزن های موجود در خطوط تولید نداریم.

از شرکت مهند رضایت کامل داریم و بسیار ممنونیم.

خوشحالیم که الک های ساخت ایران شرکت مهند، در رقابت با الک های ایتالیا و چین هست. ما دو دستگاه الک ویبره از شرکت مَهَند تهیه کردیم و همه ی دستگاه های مورد نیاز خود را برای خطوط تولید کاشی و سرامیک را از مهند خریداری خواهیم کرد. همه موارد جامع و کامل هست و خرید سرند سفارشی، تحویل الک ویبره، خدمات پس از فروش و بازدید های دوره ای رایگان به موقع انجام می شود.از تیم مهند بسیار ممنونیم.

خوشبختانه از وقتی که با شرکت خوب مهند ویبره آشنا شدیم و با آن ها همکاری کردیم، مشکلات ما در رابطه با الک ویبره کاملا حل شده است. از لحاظ فنی، کارکرد، تاسیسات، موتور و استراکچر بهترین عملکرد را دارند. از همه ی تیم فنی شرکت خوب مهند نهایت تشکر را داریم.

سرندهای ویبره مهند از لحاظ قطعات، لوازم و جنس خود الک ویبره حرف نداره. دستگاه های خارجی این قابلیت را ندارند و اگر مشکلی برای دستگاه پیش بیاد هیچ کس پاسخگو نیست، ولی شرکت مهند ویبره در هر زمانی برای الک مشکلی پیش بیاد، پاسخگو هستند و سریع رسیدگی می کنند.

الک های ویبرهای که از مهند گرفتیم، یکی از دستگاههای خوبی است که تاکنون دیدهایم. بسیار با کیفیت است. متریالی که در ساخت این دستگاه استفاده کردهاند جزو بهترینها است و نیازهای خط تولید ما را به خوبی برطرف می کند. سرندهای ویبره مهند این امکان را به ما میدهند که از دستگاه به بهترین شکل ممکن استفاده کنیم.

از بدنه موتور، دبی الک، بازدهی الک های ویبره مهند رضایت کامل داریم. بازدید دوره ای نماینده های فنی شرکت مهند ویبره خیلی برامون ارزشمند هست و تا امروز هیچ مشکلی در رابطه با دستگاه نداشتیم.

خداروشکر ما در این مدتی که از الک های ویبره مهند استفاده کردیم هیچ مشکلی نداشتیم. نیروهای مهند به طور مرتب برای بازدید و بررسی دستگاه می آیند و هر مشکلی باشد برطرف می کنند. دستگاه هیچ ایرادی ندارد و کار به درستی در حال انجام هست. ممنون بابت تمام زحمات شما

در هـنگام جسـتجـو برای رفـع مشــکـل الـک کردن لـعـاب در کـارخانه به شـرکت قـدرتمند مـهنـد ویـبـره رسـیدیـم، که سـاخـت تـخـصـصـی سرند ها را انجام می دهند. الک های ویبره، از نظر بدنه الک، قدرت موتور، دبی و خروجی مواد عالی بودند و در بین نمونه های خارجی، سرند های ویبره شرکت مهند بی نظیر بوده است.

Some of our Customers

سینا کاشی

کاشی حافظ

آریستا سرام

توس چینی

کاشی تبریز

اردکان

آریستا سرام

Client 6

گلسار فارس

تک سرام

Client 2

پردیس چینی

سهیل

یزد

پردیس آباده

دانیال سرام

صدف اردکان

کاشی کویر

Client 8

Client 1

Client 3

Client 4

After-sales Service for Vibrating Sieves

After-sales services hold particular significance in the realm of vibrating screens, serving as a pivotal factor in shaping the overall customer experience. Esteemed manufacturers of vibrating screens prioritize robust and efficient after-sales services. These services encompass routine maintenance, the provision of high-quality original spare parts, and expert technical support. Customers can swiftly and effectively address any technical inquiries, performance concerns, or repair requirements by reaching out to the company’s support team.

Moreover, training and consultancy form integral components of the after-sales service package, aiding customers in maximizing the performance of their vibrating screens. Consequently, the after-sales service provided for vibrating sieves not only contributes to preserving device efficiency and longevity but also ensures customer satisfaction and peace of mind.

Which is Correct: Vibrating Sieve or Vibrating Screen?

In Persian, the term “vibrating screen” is commonly used as a brand name for vibrating devices. Therefore, if you’re referring to a device that generates vibrations, the most suitable term is “vibrating screen”. However, “vibrating sieve” is also a valid and understandable term, typically describing a device utilized for granulation and material separation.

In essence, both “vibrating sieve” and “vibrating screen” are appropriate terms for devices that employ vibrations to sift materials.

The Distinction Between a Vibrating Sieve and a Double Round Vibrating Sieve

A double round vibrating sieve comprises two tiers and serves to segregate and sift ceramic materials across two distinct tiers. This equipment is utilized for size-based or property-based material separation, offering enhanced precision in alignment with the mesh size of the tiers within ceramic industries.

A vibrating sieve, on the other hand, is a single-tiered apparatus employed for the separation and granulation of ceramic materials, albeit with comparatively lower precision compared to its double-tiered counterpart.

In essence, both the vibrating sieve and the round vibrating sieve exemplify effective tools for the separation and granulation of materials within various industries.

Characteristics of the Optimal Vibrating Sieve

An optimal vibrating sieve should boast distinctive features and superior performance to meet the diverse requirements of the ceramic industry. Typically, reputable and experienced vibrating sieve manufacturers garner positive feedback from users. For instance, vibrating sieves from renowned brands like Mahand Ceramics are renowned for their robust power, frequency adjustability, superior manufacturing quality, and compliance with industry standards.

The best vibrating sieve adheres to stringent quality and safety standards while remaining abreast of the latest technological and engineering advancements. Furthermore, robust after-sales service capabilities and the provision of effective technical support are pivotal attributes of top-notch vibrating sieves. Opting for a vibrating sieve from a reputable brand instills confidence in users, ensuring optimal performance and durability.

Buy Mesh Lace

Mesh netting is a crucial component in the structure of vibrating sieves, with various factors such as grain size, type of ceramic material, and sieve power directly impacting device efficiency. Several considerations should be taken into account when purchasing the appropriate mesh net for a vibrating screen.

Firstly, the size of the grains of the materials to be processed by the vibrating screen must be determined. Selecting a mesh with the correct size is paramount to ensuring proper separation and processing by the vibrating sieve.

In addition to size, the mesh’s resistance should be adjusted according to the type and intensity of vibrations experienced by the vibrating screen. The mesh’s resistance should be sufficient to maintain device efficiency against the vibrations and pressures exerted by the sieve. Moreover, the material of the mesh should be carefully chosen to withstand various environmental conditions such as humidity, acidity, or heat exposure. Investing in a high-quality mesh net directly contributes to the performance of the vibrating sieve and enhances industrial processes.

Price Considerations for Vibrating Screens

The price of a vibrating screen is influenced by various factors that determine the selection and final cost. One crucial factor in pricing a vibrating sieve is its intended use and size.

Additionally, the features and technical capabilities of the device play a significant role in determining its price. Factors such as power, frequency adjustment capabilities, materials and structure of the body, compliance with standards, installation of net cleaning systems, inclusion of machine wheels, and the number of sieve floors can all impact the price. Finally, the order quantity and the number of units purchased will also affect the final pricing.

Industrial Sieve

The industrial sieve, as a vital component in various industries and production processes, is closely linked with the concept of “industrial filtration.” Serving as a fundamental piece of equipment, industrial sieves play a crucial role in the separation and granulation of ceramic materials. By utilizing vibrations, industrial sieves effectively segregate materials based on size and characteristics, thereby enhancing production efficiency and quality.

About the term “industrial standard”

The term “industrial standard” holds significant importance in this context, as it contributes to increased productivity, reduced material wastage, and improved quality control standards.

In the ceramic industry, industrial sieves are indispensable for the separation and sifting of ceramic materials, commonly integrated into production workflows. These sieves feature different plates or grids designed to segregate materials based on their sizes, with machine programming tailored to achieve precise sizing according to requirements. Deployed extensively in tile and ceramic factories, industrial sieves significantly elevate production quality and accuracy.

Overall, industrial sieves serve as fundamental tools in production and processing, enhancing efficiency, precision, and product quality. They constitute essential components of the tile and ceramic industry, contributing to its operational success and advancement.